ASTM A106 Pipe

What is ASTM A106 steel pipe?

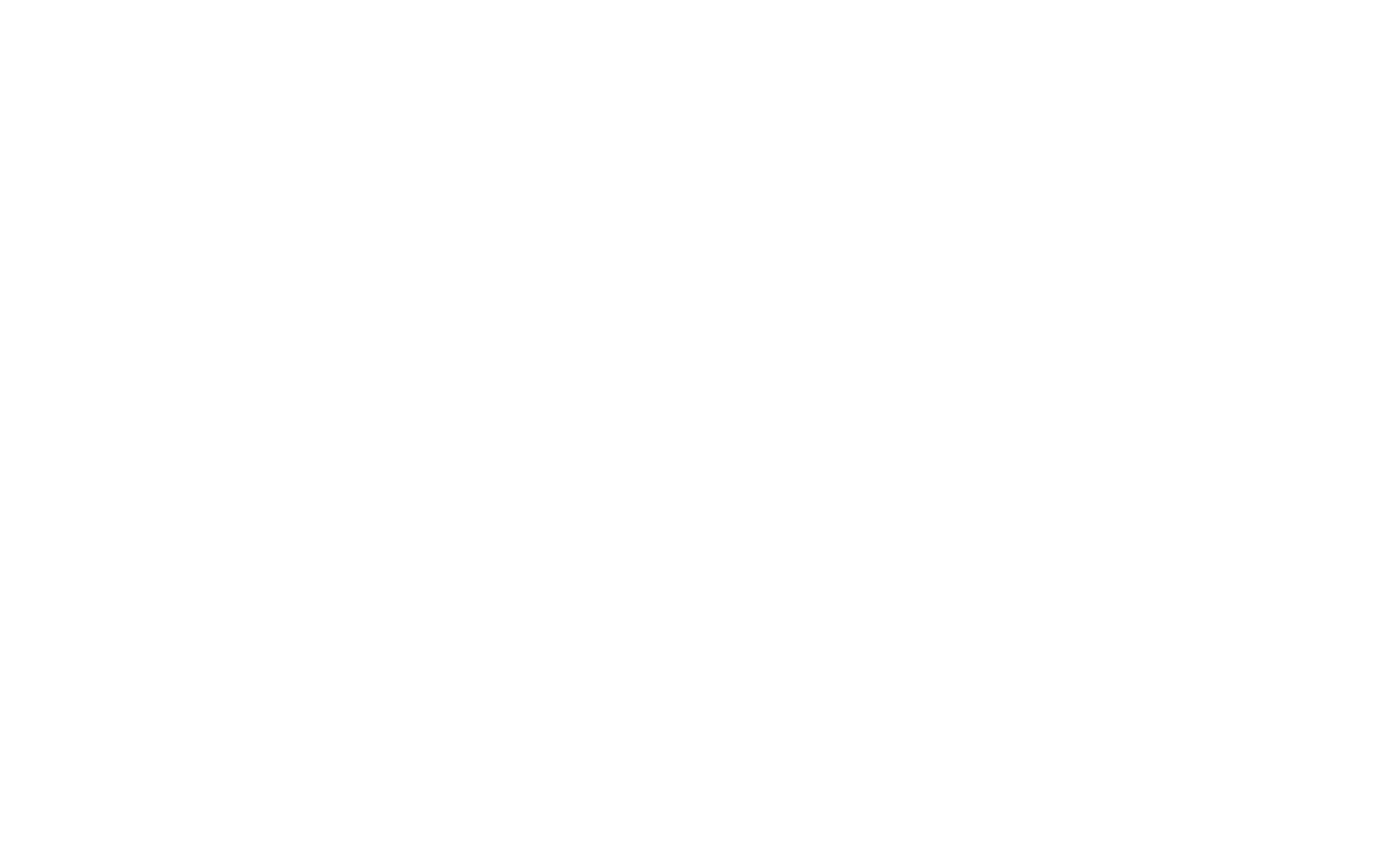

ASTM A106 Seamless Pressure Pipe (also known as ASME SA106 pipe) covers seamless carbon steel nominal wall pipe for high-temperature service. Suitable for bending, flagging, and similar forming operations. This specification covers seamless carbon steel pipe for high-temperature service. A106 seamless carbon steel pipe shall be suitable for bending, flanging, and similar forming operations, and for welding. When the steel is to be welded, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service will be utilized. Supplementary requirements of an optional nature are provided for seamless pipe intended for use in applications where a superior grade of pipe is required. Applications include high-pressure vessels, nozzles, and critical applications requiring the highest material integrity. A106 seamless carbon steel pipe is easily weldable using various welding procedures. This makes it a preferred choice for pressure piping associated with various Oil, Gas, and Industrial applications. Seamless pipe is also very common in petrochemical industries for carrying high-pressure fluid.

Process

Killed steel, with primary melting process being open-hearth, basic-oxygen, or electric-furnace, possibly combined with separate degassing or refining.

Steel cast in ingots or strand cast is permissible.

Hot-finished pipe need not be heat treated.

Cold-drawn pipe shall be heat treated after the final cold draw pass.

ASTM A106 Hot-finished pipe need not be heat treated. Cold-drawn pipe shall be heat treated after the final cold draw pass at a temperature of 1200°F (650°C) or higher.

Chemical Requirements

| Grade | Grade A | Grade B | Grade C |

| Carbon max. % | 0.25 | 0.30* | 0.35* |

| *Manganese % | 0.27 to 0.93 | *0.29 to 1.06 | *0.29 to 1.06 |

| Phosphorous, max. % | 0.035 | 0.035 | 0.035 |

| Sulfur, max. % | 0.035 | 0.035 | 0.035 |

| Silicon, min.% | 0.1 | 0.1 | 0.1 |

| Chrome, max. % | 0.4 | 0.4 | 0.4 |

| Copper, max. % | 0.4 | 0.4 | 0.4 |

| Molybdenum, max. % | 0.15 | 0.15 | 0.15 |

| Nickel, max. % | 0.4 | 0.4 | 0.4 |

| Vanadium, max.% | 0.08 | 0.08 | 0.08 |

Note: Total of Cr, Cu, Mo, Ni, and V shall not exceed 1%

Tensile Requirements

| Seamless | |||

| Grade A | Grade B | Grade C | |

| Tensile Strength, min., psi | 48,000 | 60,000 | 70,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 40,000 |

Size Chart of ASTM A106 seamless carbon steel pipe

| Pipe Size | Wall Thickness | OD | ID | Schedule |

| 1/8″ | 0.068 | 0.405 | 0.269 | 40 |

| 1/8″ | 0.095 | 0.405 | 0.215 | 80 |

| 1/4″ | 0.088 | 0.54 | 0.364 | 40 |

| 1/4″ | 0.119 | 0.54 | 0.302 | 80 |

| 3/8″ | 0.091 | 0.675 | 0.493 | 40 |

| 3/8″ | 0.126 | 0.675 | 0.423 | 80 |

| 1/2″ | 0.109 | 0.84 | 0.622 | 40 |

| 1/2″ | 0.147 | 0.84 | 0.546 | 80 |

| 1/2″ | 0.188 | 0.84 | 0.464 | 160 |

| 1/2″ | 0.294 | 0.84 | 0.252 | XXH |

| 3/4″ | 0.113 | 1.05 | 0.824 | 40 |

| 3/4″ | 0.154 | 1.05 | 0.742 | 80 |

| 3/4″ | 0.219 | 1.05 | 0.612 | 160 |

| 3/4′ | 0.308 | 1.05 | 0.434 | XXH |

| 1″ | 0.133 | 1.315 | 1.049 | 40 |

| 1″ | 0.179 | 1.315 | 0.957 | 80 |

| 1″ | 0.25 | 1.315 | 0.815 | 160 |

| 1″ | 0.358 | 1.315 | 0.599 | XXH |

| 1-1/4″ | 0.14 | 1.66 | 1.38 | 40 |

| 1-1/4″ | 0.191 | 1.66 | 1.278 | 80 |

| 1-1/4″ | 0.25 | 1.66 | 1.16 | 160 |

| 1-1/4″ | 0.382 | 1.66 | 0.896 | XXH |

| 1-1/2″ | 0.145 | 1.9 | 1.61 | 40 |

| 1-1/2″ | 0.2 | 1.9 | 1.5 | 80 |

| 1-1/2″ | 0.281 | 1.9 | 1.338 | 160 |

| 1-1/2″ | 0.4 | 1.9 | 1.1 | XXH |

| 2″ | 0.154 | 2.375 | 2.067 | 40 |

| 2″ | 0.218 | 2.375 | 1.939 | 80 |

| 2″ | 0.343 | 2.375 | 1.689 | 160 |

| 2″ | 0.436 | 2.375 | 1.503 | XXH |

| 2-1/2″ | 0.203 | 2.875 | 2.469 | 40 |

| 2-1/2″ | 0.276 | 2.875 | 2.323 | 80 |

| 2-1/2″ | 0.375 | 2.875 | 2.125 | 160 |

| 2-1/2″ | 0.552 | 2.875 | 1.771 | XXH |

| 3″ | 0.216 | 3.5 | 3.068 | 40 |

| 3″ | 0.3 | 3.5 | 2.9 | 80 |

| 3″ | 0.438 | 3.5 | 2.624 | 160 |

| 3″ | 0.6 | 3.5 | 2.3 | XXH |

| 3-1/2″ | 0.226 | 4 | 3.548 | 40 |

| 3-1/2″ | 0.318 | 4 | 3.364 | 80 |

| 3-1/2″ | 0.636 | 4 | 2.728 | XXH |

| 4″ | 0.237 | 4.5 | 4.026 | 40 |

| 4″ | 0.337 | 4.5 | 3.826 | 80 |

| 4″ | 0.438 | 4.5 | 3.624 | 120 |

| 4″ | 0.531 | 4.5 | 3.438 | 160 |

| 4″ | 0.671 | 4.5 | 3.18 | XXH |

| 5″ | 0.258 | 5.563 | 5.047 | 40 |

| 5″ | 0.375 | 5.563 | 4.813 | 80 |

| 5″ | 0.5 | 5.563 | 4.563 | 120 |

| 5″ | 0.625 | 5.563 | 4.313 | 160 |

| 5″ | 0.75 | 5.563 | 4.063 | XXH |

| 6″ | 0.28 | 6.625 | 6.065 | 40 |

| 6″ | 0.432 | 6.625 | 5.761 | 80 |

| 6″ | 0.562 | 6.625 | 5.501 | 120 |

| 6″ | 0.719 | 6.625 | 5.187 | 160 |

| 6″ | 0.864 | 6.625 | 4.897 | XXH |

| 8″ | 0.322 | 8.625 | 7.981 | 40 |

| 8″ | 0.5 | 8.625 | 7.625 | 80 |

| 8″ | 0.719 | 8.625 | 7.187 | 120 |

| 8″ | 0.875 | 8.625 | 6.875 | XXH |

| 8″ | 0.906 | 8.625 | 6.813 | 160 |

| 10″ | 0.365 | 10.75 | 10.02 | 40 |

| 10″ | 0.5 | 10.75 | 9.75 | 60/XH |

| 10″ | 0.594 | 10.75 | 9.562 | 80 |

| 10″ | 0.719 | 10.75 | 9.312 | 100 |

| 10″ | 0.844 | 10.75 | 9.062 | 120 |

| 10″ | 1 | 10.75 | 8.75 | 140/XXH |

| 10″ | 1.125 | 10.75 | 8.5 | 160 |

| 12″ | 0.375 | 12.75 | 12 | STD |

| 12″ | 0.406 | 12.75 | 11.938 | 40 |

| 12″ | 0.5 | 12.75 | 11.75 | XH |

| 12″ | 0.562 | 12.75 | 11.626 | 60 |

| 12″ | 0.688 | 12.75 | 11.374 | 80 |

| 12″ | 0.844 | 12.75 | 11.062 | 100 |

| 12″ | 1 | 12.75 | 10.75 | 120/XXH |

| 12″ | 1.125 | 12.75 | 10.5 | 140 |

| 12″ | 1.312 | 12.75 | 10.126 | 160 |

| 14″ | 0.375 | 14 | 13.25 | 30/STD |

| 14″ | 0.438 | 14 | 13.124 | 40 |

| 14″ | 0.5 | 14 | 13 | XH |

| 14″ | 0.594 | 14 | 12.812 | 60 |

| 14″ | 0.75 | 14 | 12.5 | 80 |

| 14″ | 1.094 | 14 | 11.812 | 120 |

| 14″ | 1.25 | 14 | 11.5 | 140 |

| 14″ | 1.406 | 14 | 11.188 | 160 |

| 16″ | 0.375 | 16 | 15.25 | 30/STD |

| 16″ | 0.5 | 16 | 15 | 40/XH |

| 16″ | 0.656 | 16 | 14.688 | 60 |

| 16″ | 0.844 | 16 | 14.312 | 80 |

| 16″ | 1.031 | 16 | 13.938 | 100 |

| 16″ | 1.219 | 16 | 13.562 | 120 |

| 16″ | 1.438 | 16 | 13.124 | 140 |

| 16″ | 1.594 | 16 | 12.812 | 160 |

| 18″ | 0.375 | 18 | 17.25 | STD |

| 18″ | 0.438 | 18 | 17.124 | 30 |

| 18″ | 0.5 | 18 | 17 | XH |

| 18″ | 0.562 | 18 | 16.876 | 40 |

| 18″ | 0.75 | 18 | 16.5 | 60 |

| 18″ | 0.938 | 18 | 16.124 | 80 |

| 18″ | 1.156 | 18 | 15.688 | 100 |

| 18″ | 1.375 | 18 | 15.25 | 120 |

| 18″ | 1.562 | 18 | 14.876 | 140 |

| 18″ | 1.781 | 18 | 14.438 | 160 |

| 20″ | 0.375 | 20 | 19.25 | 20/STD |

| 20″ | 0.5 | 20 | 19 | 30/XH |

| 20″ | 0.594 | 20 | 18.812 | 40 |

| 20″ | 0.812 | 20 | 18.376 | 60 |

| 20″ | 1.031 | 20 | 17.938 | 80 |

| 20″ | 1.281 | 20 | 17.438 | 100 |

| 20″ | 1.5 | 20 | 17 | 120 |

| 20″ | 1.75 | 20 | 16.5 | 140 |

| 20″ | 1.969 | 20 | 16.062 | 160 |

| 22″ | 0.375 | 22 | 21.25 | 20/STD |

| 22″ | 0.5 | 22 | 21 | 30/XH |

| 24″ | 0.375 | 24 | 23.25 | 20/STD |

| 24″ | 0.5 | 24 | 23 | XH |

| 24″ | 0.562 | 24 | 22.876 | 30 |

| 24″ | 0.969 | 24 | 22.062 | 60 |

| 24″ | 1.219 | 24 | 21.562 | 80 |

| 24″ | 1.534 | 24 | 20.932 | 100 |

| 24″ | 1.812 | 24 | 20.376 | 120 |

| 24″ | 2.062 | 24 | 19.876 | 140 |

http://admin@cnsteelpiping.comASTM A106 seamless carbon steel pipe application

- Oil Refineries.

- Petrochemicals.

- Power Generation (Nuclear/Thermal)

- Steel.

- Sugar.

- Construction industry.

- Boilers.

- Heat exchangers.

- Pressure vessels.

- General Engineering Purposes.

We are a professional Carbon Steel Pipe supplier. We provide Carbon Steel Pipe of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:admin@cnsteelpiping.com