ASTM A358 Pipe

What is ASTM A358 Steel Pipe?

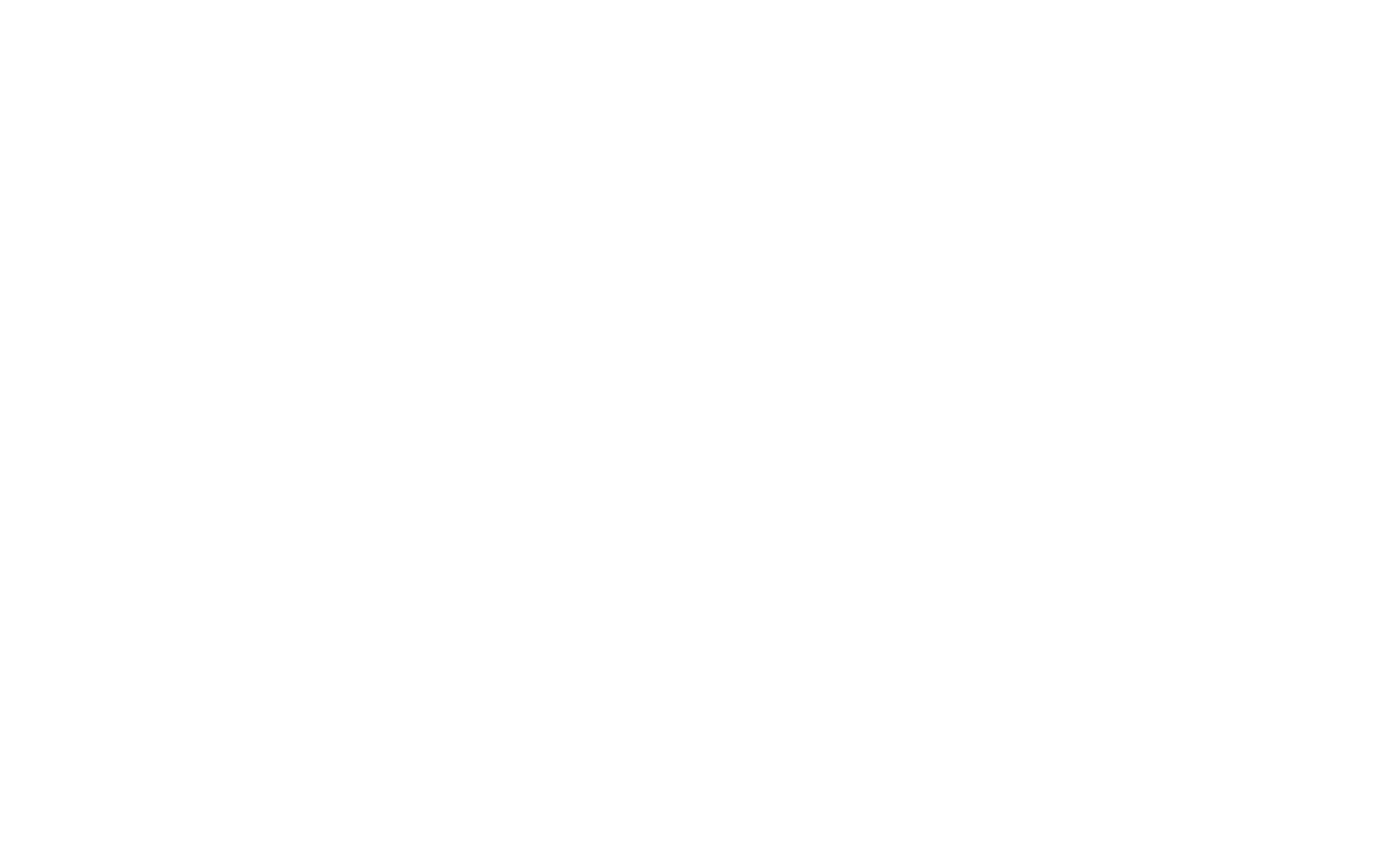

The ASTM A358 pipe is made with electric fusion welding. The materials for the ASTM A358 have 18% chromium, 8% nickel and manganese, silicon, sulfur, and phosphorus in the composition. The much higher resistant a358 contains molybdenum in the composition. The molybdenum content makes the material resistant to chloride ion corrosion. The A358 is the most used because of its strength and cost efficiency. The astm a358 stainless steel pipe comes in sizes ranging from 8 inches to 72 inches. The thickness of the pipes ranges from 3mm to 60mm. The astm a358 uns s31254 ranges in length up to 6 meters. ASTM A358 Stainless Steel EFW Pipes can come in different finishes such as pickled, BA finish, No 4 finish, and electropolished. The astm a358 has slight mechanical differences.

ASTM A358 / A358M is standard Specification for Electric-Fusion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe for High-Temperature Service and General Applications

This specification covers electric-fusion-welded austenitic chromium-nickel stainless steel pipe suitable for corrosive or high-temperature service, or both, or for general applications. The pipes shall be sorted into five different classes.

ASTM A358 CL1 - ASTM A358 Class 1 Pipe shall be double welded by processes employing filler metal in all passes and shall be completely radiographed.

ASTM A358 CL2 - ASTM A358 Class 2 Pipe shall be double welded by processes employing filler metal in all passes, no radiography is required.

ASTM A358 CL3 - ASTM A358 Class 3 Pipe shall be single welded by processes employing filler metal in all passes and shall be completely radiographed.

ASTM A358 CL4 - Same as ASTM A358 Class 3 except that the weld pass exposed to the inside pipe surface may be made without the addition of filler metal.

ASTM A358 CL5 - ASTM A358 Class 5 Pipe shall be double welded by processes employing filler metal in all passes and shall be spot radiographed.

A358 Steel Pipe Chemical Composition

| A358 GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| TP304 | S3040 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | 0.035 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-13.0 | |||||

| TP304H | S30409 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304N | S30451 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-18.0 | 0.10-0.16 | |||

| TP304LN | S30453 | 0.035 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-12.0 | 0.10-0.16 | |||

| ASME SA358 TP309S | S30908 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | 0.75 | |||

| ASME SA358 TP309H | S30909 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | ||||

| ASME SA358 TP309Cb | S30940 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10xC min 1.10 max | ||

| ASME SA358 TP309HCb | S30941 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-16.0 | 0.75 | 10xC min 1.10 nmax | ||

| ASME SA358 TP310S | S3108 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 24.0-26.0 | 19.0-22.0 | 0.75 | |||

| ASME SA358 TP310H | S3109 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 24.0-26.0 | 19.0-22.0 | ||||

| ASME SA358 TP310Cb | S31040 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10xC min 1.10 max | ||

| ASME SA358 TP310HCb | S31041 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 24.0-26.0 | 19.0-22.0 | 0.75 | 10xC min 1.10 max | ||

| ASME A358 TP316 | S3160 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| ASTM SA358 TP316L | S31603 | 0.035 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |||

| ASTM SA358 TP316H | S31609 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316Ti | S31635 | 0.08 | 2.0 | 0.045 | 0.030 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 5x (C-N) -0.70 | 0.10 | |

| TP316N | S31651 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.10-0.16 | ||

| TP316LN | S31653 | 0.035 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | 0.10-0.16 | ||

| ASME SA358 TP317 | S3170 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 10.0-14.0 | 3.0-4.0 | |||

| ASME SA358 TP317L | S31703 | 0.035 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | |||

| TP321 | S3210 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | 0.10 | |||

| TP321H | S32109 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | 0.10 | |||

| TP347 | S3470 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-13.0 | ||||

| TP347H | S34709 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-13.0 | ||||

| TP347LN | S34751 | 0.05-0.02 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-13.0 | 0.20- 50.0 | 0.06-0.10 | ||

| TP348 | S3480 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-13.0 | ||||

| ASME SA358 TP348H | S34809 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-13.0 |

ASME SA358 Steel Pipes Mechanical Properties

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

ASTM A358 Steel Size Chart

| Nominal | Outside | Nominal Wall Thickness(mm) | ||||||||

| Diameter | Diameter | ASME B36.19M | ASME B36.10M | |||||||

| NPS | (mm) | SCH5S | SCH10S | SCH40S | SCH80S | SCH5 | SCH10 | SCH20 | STD | XS |

| 1/4 | 13.72 | - | 1.65 | 2.24 | 3.02 | - | 1.65 | - | 2.24 | 3.02 |

| 3/8 | 17.15 | - | 1.65 | 2.31 | 3.2 | - | 1.65 | - | 2.31 | 3.2 |

| 1/2 | 21.34 | 1.65 | 2.11 | 2.77 | 3.73 | 1.65 | 2.11 | - | 2.77 | 3.73 |

| 3/4 | 26.67 | 1.65 | 2.11 | 2.87 | 3.91 | 1.65 | 2.11 | - | 2.87 | 3.91 |

| 1 | 33.4 | 1.65 | 2.77 | 3.38 | 4.55 | 1.65 | 2.77 | - | 3.38 | 4.55 |

| 1 1/4 | 42.16 | 1.65 | 2.77 | 3.56 | 4.85 | 1.65 | 2.77 | - | 3.56 | 4.85 |

| 1 1/2 | 48.26 | 1.65 | 2.77 | 3.68 | 5.08 | 1.65 | 2.77 | - | 3.68 | 5.08 |

| 2 | 60.33 | 1.65 | 2.77 | 3.91 | 5.54 | 1.65 | 2.77 | - | 3.91 | 5.54 |

| 2 1/2 | 73.03 | 2.11 | 3.05 | 5.16 | 7.01 | 2.11 | 3.05 | - | 5.16 | 7.01 |

| 3 | 88.9 | 2.11 | 3.05 | 5.49 | 7.62 | 2.11 | 3.05 | - | 5.49 | 7.62 |

| 3 1/2 | 101.6 | 2.11 | 3.05 | 5.74 | 8.08 | 2.11 | 3.05 | - | 5.74 | 8.08 |

| 4 | 114.3 | 2.11 | 3.05 | 6.02 | 8.56 | 2.11 | 3.05 | - | 6.02 | 8.56 |

| 5 | 141.3 | 2.77 | 3.4 | 6.55 | 9.53 | 2.77 | 3.4 | - | 6.55 | 9.53 |

| 6 | 168.28 | 2.77 | 3.4 | 7.11 | 10.97 | 2.77 | 3.4 | - | 7.11 | 10.97 |

| 8 | 219.08 | 2.77 | 3.76 | 8.18 | 12.7 | 2.77 | 3.76 | 6.35 | 8.18 | 12.7 |

| 10 | 273.05 | 3.4 | 4.19 | 9.27 | 12.7 | 3.4 | 4.19 | 6.35 | 9.27 | 12.7 |

| 12 | 323.85 | 3.96 | 4.57 | 9.53 | 12.7 | 3.96 | 4.57 | 6.35 | 9.53 | 12.7 |

| 14 | 355.6 | 3.96 | 4.78 | 9.53 | 12.7 | 3.96 | 6.35 | 7.92 | 9.53 | 12.7 |

| 16 | 406.4 | 4.19 | 4.78 | 9.53 | 12.7 | 4.19 | 6.35 | 7.92 | 9.53 | 12.7 |

| 18 | 457.2 | 4.19 | 4.78 | 9.53 | 12.7 | 4.19 | 6.35 | 7.92 | 9.53 | 12.7 |

| 20 | 508 | 4.78 | 5.54 | 9.53 | 12.7 | 4.78 | 6.35 | 9.53 | 9.53 | 12.7 |

| 22 | 558.8 | 4.78 | 5.54 | - | - | 4.78 | 6.35 | 9.53 | 9.53 | 12.7 |

| 24 | 609.6 | 5.54 | 6.35 | 9.53 | 12.7 | 5.54 | 6.35 | 9.53 | 9.53 | 12.7 |

| 26 | 660.4 | - | - | - | - | - | 7.92 | 12.7 | 9.53 | 12.7 |

| 28 | 711.2 | - | - | - | - | - | 7.92 | 12.7 | 9.53 | 12.7 |

| 30 | 762 | 6.35 | 7.92 | - | - | 6.35 | 7.92 | 12.7 | 9.53 | 12.7 |

| 32 | 812.8 | Thickness :6.35~30mm | ||||||||

| | | | | |||||||||

| 84 | 2133.6 | |||||||||

| Remark

| (1)Marking:Within production capability. | |||||||||

| (2)Other nominal diameter and wall thickness subject to the approval of vendor and client. | ||||||||||

| (3)Calculating formula for the value of mass (kg/m):304/L[W=0.02491t(D-t)], 316/L[W=0.02507t(D-t)] | ||||||||||

(Dimensions of astm a358 welded and seamless stainless steel pipes: The decimal thickness listed for the respective pipe sizes represents their nominal or average wall dimensions.

| Product | NPS Designator | Outside Diameter | Nominal Wall Thickness | ||||||||

| in. | mm | Schedule 5SA | Schedule 10SA | Schedule 40SA | Schedule 80SA | ||||||

| in. | mm | in. | mm | in. | mm | in. | mm | ||||

| 8 | 8.625 | 219.08 | 0.109 | 2.77 | 0.148 | 3.76 | 0.322 | 8.18 | 0.500 | 12.70 | |

| 10 | 10.750 | 273.05 | 0.134 | 3.40 | 0.165 | 4.19 | 0.365 | 9.27 | 0.500B | 12.70B | |

| 12 | 12.750 | 323.85 | 0.156 | 3.96 | 0.180 | 4.57 | 0.375B | 9.52B | 0.500B | 12.70B | |

| 14 | 14.000 | 355.60 | 0.156 | 3.96 | 0.188B | 4.78B | ... | ... | ... | ... | |

| 16 | 16.000 | 406.40 | 0.165 | 4.19 | 0.188B | 4.78B | ... | ... | ... | ... | |

| 18 | 18.000 | 457.20 | 0.165 | 4.19 | 0.188B | 4.78B | ... | ... | ... | ... | |

| 20 | 20.000 | 508.00 | 0.188 | 4.78 | 0.188B | 4.78B | ... | ... | ... | ... | |

| 22 | 22.000 | 558.80 | 0.188 | 4.78 | 0.218B | 5.54B | ... | ... | ... | ... | |

| 24 | 24.000 | 609.60 | 0.218 | 5.54 | 0.250 | 6.35 | ... | ... | ... | ... | |

| 30 | 30.000 | 762.00 | 0.250 | 6.35 | 0.312 | 7.92 | ... | ... | ... | ... | |

ASTM A358 Steel Pipes Tolerance

| NPS Designator | Permissible Variations in Outside Diameter | |

| Over In. | Under In. | |

| 1/8 to 1-1/2, incl | 1/64 (0.015) | 1/32 (0.031) |

| Over 1-1/2 to 4, incl | 1/32 (0.031) | 1/32 (0.031) |

| Over 4 to 8, incl | 1/16 (0.062) | 1/32 (0.031) |

| Over 8 to 18, incl | 3/23 (0.093) | 1/32 (0.031) |

Nominal Wall Thickness

| NPS Designator | Outside Diameter in. | Schedule 5S in. | Schedule 10S in. | Schedule 40S in. | Schedule 80S in. |

| 1/4 | 0.540 | 0.065 | 0.088 | 0.119 | |

| 3/8 | 0.675 | 0.065 | 0.091 | 0.126 | |

| 1/2 | 0.840 | 0.065 | 0.083 | 0.109 | 0.147 |

| 3/4 | 1.050 | 0.065 | 0.083 | 0.113 | 0.154 |

| 1.0 | 1.315 | 0.065 | 0.109 | 0.133 | 0.179 |

| 1 1/4 | 1.660 | 0.065 | 0.109 | 0.140 | 0.191 |

| 1 1/2 | 1.900 | 0.065 | 0.109 | 0.145 | 0.200 |

| 2 | 2.375 | 0.065 | 0.109 | 0.154 | 0.218 |

| 2 1/2 | 2.875 | 0.083 | 0.120 | 0.203 | 0.276 |

| 3 | 3.500 | 0.083 | 0.120 | 0.216 | 0.300 |

| 3 1/2 | 4.000 | 0.083 | 0.120 | 0.226 | 0.318 |

| 4 | 4.500 | 0.083 | 0.120 | 0.237 | 0.337 |

| 5 | 5.563 | 0.109 | 0.134 | 0.258 | 0.375 |

| 6 | 6.625 | 0.109 | 0.134 | 0.280 | 0.432 |

| 8 | 8.625 | 0.109 | 0.148 | 0.322 | 0.500 |

| 10 | 10.750 | 0.134 | 0.165 | 0.365 | 0.500 |

| 12 | 12.750 | 0.156 | 0.180 | 0.375 | 0.500 |

Wall Thickness Tolerance Astm A358 Steel Pipe

| NPS | ASTM A358 Steel Pipe Tolerance, % | |

| + | – | |

| 1/8-2 1 /2 | 20.0 | 12.5 |

| 3~18, t/D≤ 5% | 22.5 | 12.5 |

| 3~18, t/D> 5% | 15.0 | 12.5 |

| ≥ 20, welded | 17.5 | 12.5 |

| ≥ 20, seamless, t/D≤ 5% | 22.5 | 12.5 |

| ≥ 20, seamless, t/D> 5% | 15.0 | 12.5 |

Application of ASTM A358 Steel Pipe

- Cryogenic Industry

- LNG Gas

- Offshore Industry

- Process Plants

- Sub Sea

- Refineries

- Shipbuilding

- Food & Beverage Industry

- Construction Industry

- Nuclear Industry

- Thermal & Power Plants

- Petrochemical, Boilers Industry

- Cement Industry

- Geothermal Plants

- Heat Exchangers

- Oil and Gas Equipment and Piping Works

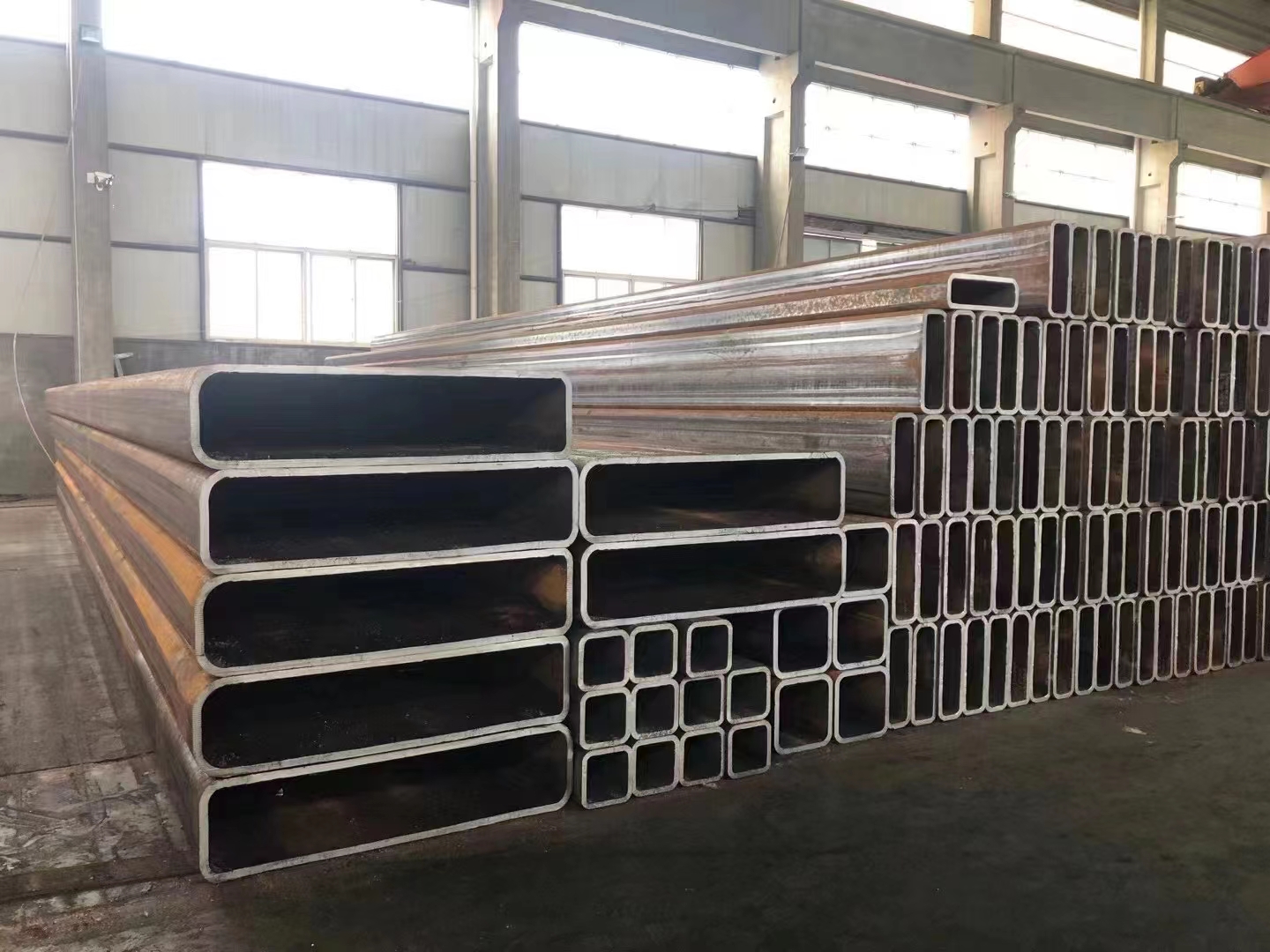

We are a professional Stainless Steel Pipe supplier. We provide Stainless Steel Pipe of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:admin@cnsteelpiping.com