ASTM A53 Pipe

What is ASTM A53 Steel Pipe

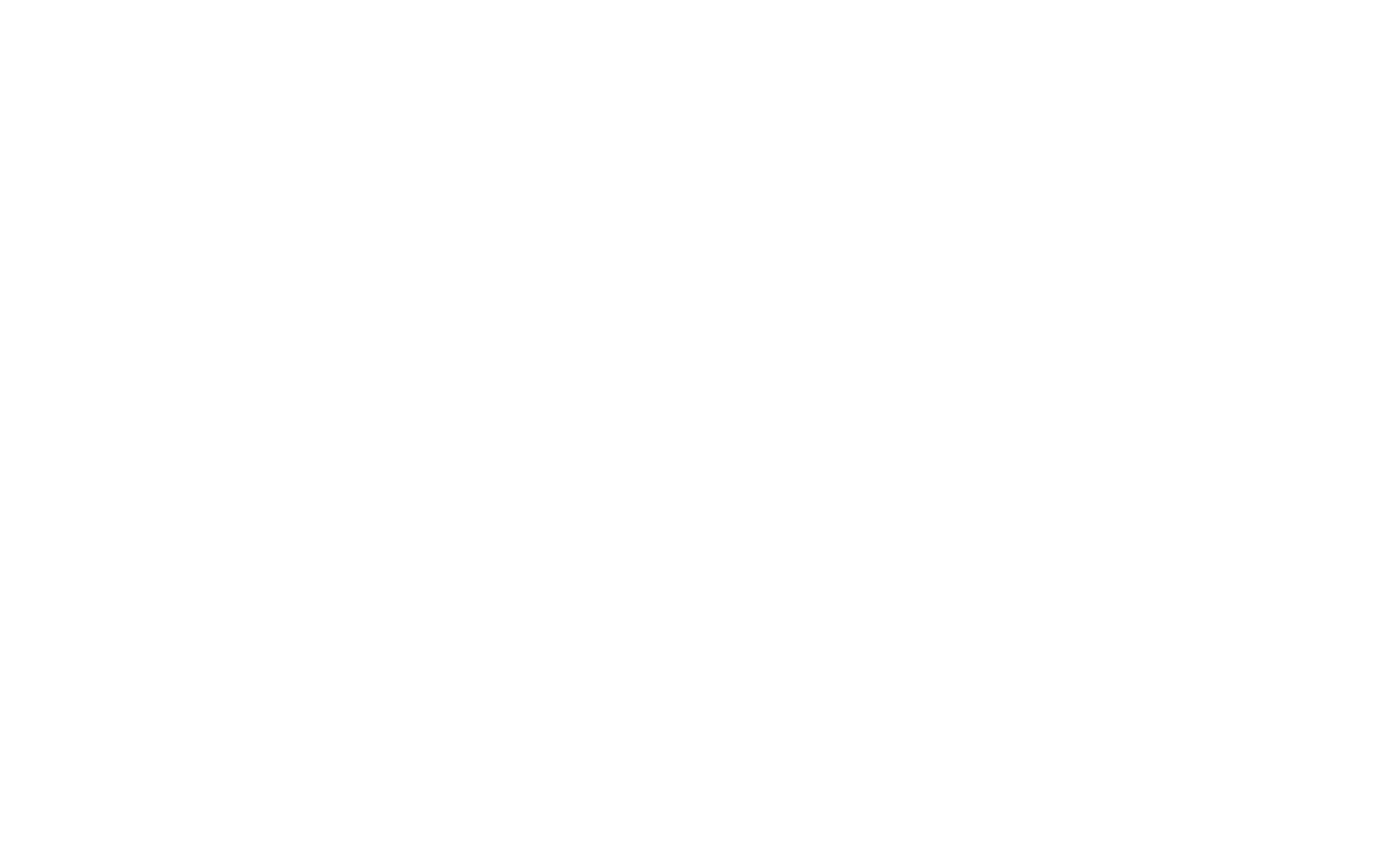

Identical to ASME SA-53, ASTM A53 steel pipe is the standard specification for seamless and welded black and hot-dipped galvanized (zinc-coated) steel pipe in NPS 1/8 (DN 6) to NPS 26 (DN650) with nominal wall thickness. The steel pipe having other dimensions can also be furnished provided that such pipe complies with all other requirements of the specification. The “black steel” refers to a dark-colored iron oxide scaly appearance which naturally results from the pipe’s fabrication process. The hot-dipped galvanization is provided for corrosion protection purposes.

A53 Steel Pipe Raw Material – Carbon Steel Pipe

The steel for making ASTM A53 pipe (both for seamless and welded) shall be according following processes: open hearth electric furnace, or basic oxygen.

Raw steel material of different grades are independently strand cast identification of resultant transition material is needed. Manufacturer should remove transition material by any established procession that could clearly separate the grades.

The welding seam for ERW welding processes in ASTM A53 Grade B pipe should be done heat treatment after welding to a min of 540℃(1000℉).

Consequently, there is no untempered martensite remains, or use the other ways of non untempered martensite remains.

For cold expanded, the expansion amount shall not exceed 1 1/2% of the pipe diameter.

Material Types for ASTM A53 Steel Pipe Standard

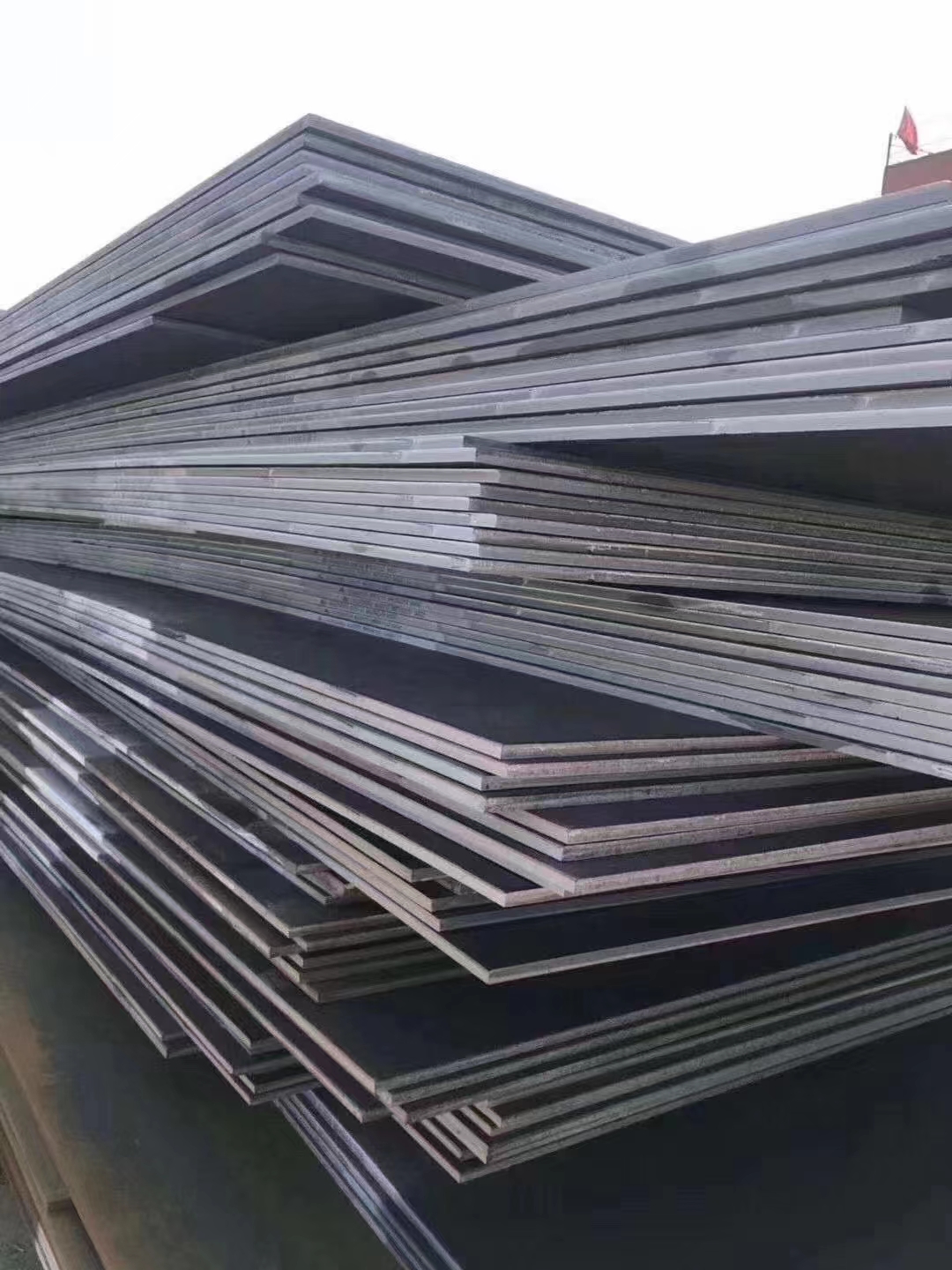

a. Seamless Type S, has grade A and B.

b. Welded Type E (ERW), Grade A and B.

c. Furnace Welded Type F, Grade A only.

ASTM A53 Steel Pipe Applications

Transmission: Oil and gas pipeline systems, water treatment, mineral slurry

Construction and Structure: Buildings, underground water drilling, boiler water transmission

Machine Parts: Machining to spare parts

Power station: Wind Turbines, Anti-Static tube

Chemical requirements of ASTM A53 Steel Pipe

| Element | Type S (seamless) | Type E | Type F | ||

| (electric- resistance welded) | (furnace- welded pipe) | ||||

| Grade A | Grade B | Grade A | Grade B | Grade A | |

| Carbon max. % | 0.25 | 0.30 | 0.25 | 0.30 | 0.3 |

| Manganese % | 0.95 | 1.2 | 0.95 | 1.2 | 1.2 |

| Phosphorous, max. % | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Sulfur, max. % | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 |

| Copper, max.% | 0.40 | 0.40 | 0.40 | 0.40 | 0.4 |

| Nickel, max. % | 0.40 | 0.40 | 0.40 | 0.40 | 0.4 |

| Chromium, max. % | 0.40 | 0.40 | 0.40 | 0.40 | 0.4 |

| Molybdenum, max. % | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| Vanadium, max. % | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

Hot-dipped Galvanizing:

Sets standards for coating of pipe with zinc inside and outside by the hot-dipped process. Weight of coating must not average less than 1.8 oz. per square foot and not less than 1.6 oz. per square foot.

PERMISSIBLE VARIATIONS IN WALL THICKNESS

The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified.

PERMISSIBLE VARIATIONS IN WEIGHTS PER FOOT

Plus or minus 10%

PERMISSIBLE VARIATIONS IN OUTSIDE DIAMETER

Outside Diameter at any point shall not vary from standard specified more than:

| For NPS 1 1/2 and Smaller Sizes | For NPS 2 and Larger Sizes | |||

| 1/64″ | 1/32″ under | 1% over | 1%under | |

Mechanical Properties Comparison of ASTM A53 Steel Pipe

| Seamless and Electric-resistance-welded | Continuous-Welded | ||

| Grade A | Grade B | ||

| Tensile Strength, min., psi | 48,000 | 60,000 | 45,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 25,000 |

Size Chart of ASTM A53 Steel Pipe

| NPS | O.D. | Nominal Wall Thickness | |||||||||||||||

| DN | Inch | mm | SCH5S | SCH10S | SCH10 | SCH20 | SCH30 | SCH40 | SCH60 | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | Sth | XS | XXS |

| 50 | 2″ | 60.3 | 1.65 | 2.77 | – | – | – | 3.91 | – | 5.54 | – | – | – | 8.74 | 3.91 | 5.54 | 11.07 |

| 65 | 2 1/2″ | 73 | 2.11 | 3.05 | – | – | – | 5.16 | – | 7.01 | – | – | – | 9.53 | 5.16 | 7.01 | 14.02 |

| 80 | 3″ | 88.9 | 2.11 | 3.05 | – | – | – | 5.49 | – | 7.62 | – | – | – | 11.13 | 5.49 | 7.52 | 15.24 |

| 90 | 3 1/2″ | 101.6 | 2.11 | 3.05 | – | – | – | 5.74 | – | 8.08 | – | – | – | – | 5.74 | 8.08 | – |

| 100 | 4″ | 114.3 | 2.11 | 3.05 | – | – | – | 6.02 | – | 8.58 | – | 11.13 | – | 13.49 | 6.02 | 8.56 | 17.12 |

| 125 | 5″ | 141.3 | 2.77 | 3.4 | – | – | – | 6.55 | – | 9.53 | – | 12.7 | – | 15.88 | 6.55 | 9.53 | 18.05 |

| 150 | 6″ | 168.3 | 2.77 | 3.4 | – | – | – | 7.11 | – | 10.97 | – | 14.27 | – | 18.26 | 7.11 | 10.97 | 21.95 |

| 200 | 8″ | 219.1 | 2.77 | 3.76 | – | 6.35 | 7.04 | 8.18 | 10.31 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 8.18 | 12.7 | 22.23 |

| 250 | 10″ | 273.1 | 3.4 | 4.19 | – | 6.35 | 7.8 | 9.27 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 9.27 | 12.7 | 25.4 |

| 300 | 12″ | 323.9 | 3.96 | 4.57 | – | 6.35 | 8.38 | 10.31 | 14.27 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 9.53 | 12.7 | 25.4 |

| 350 | 14″ | 355.5 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 11.13 | 15.09 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | 9.53 | 12.7 | – |

| 400 | 16″ | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 12.7 | 16.66 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | 9.53 | 12.7 | – |

| 450 | 18″ | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 14.27 | 19.05 | 23.83 | 39.36 | 34.93 | 39.67 | 45.24 | – | – | – |

| 500 | 20″ | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 15.09 | 20.62 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | – | – | – |

| 550 | 22″ | 558.8 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | – | 22.23 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | – | – | – |

| 600 | 24″ | 609.6 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 17.48 | 24.61 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | – | – | – |

ASTM A53 seamless steel pipe and welded steel pipe application

- Oil Refineries.

- Petrochemicals.

- Power Generation (Nuclear/Thermal)

- Steel.

- Sugar.

- Construction industry.

- Boilers.

- Heat exchangers.

- Pressure vessels.

- General Engineering Purposes.

We are a professional Carbon Steel Pipe supplier. We provide Carbon Steel Pipe of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:admin@cnsteelpiping.com