EN 10219-1 Welded Pipes

What is EN 10219-1 Steel Pipe?

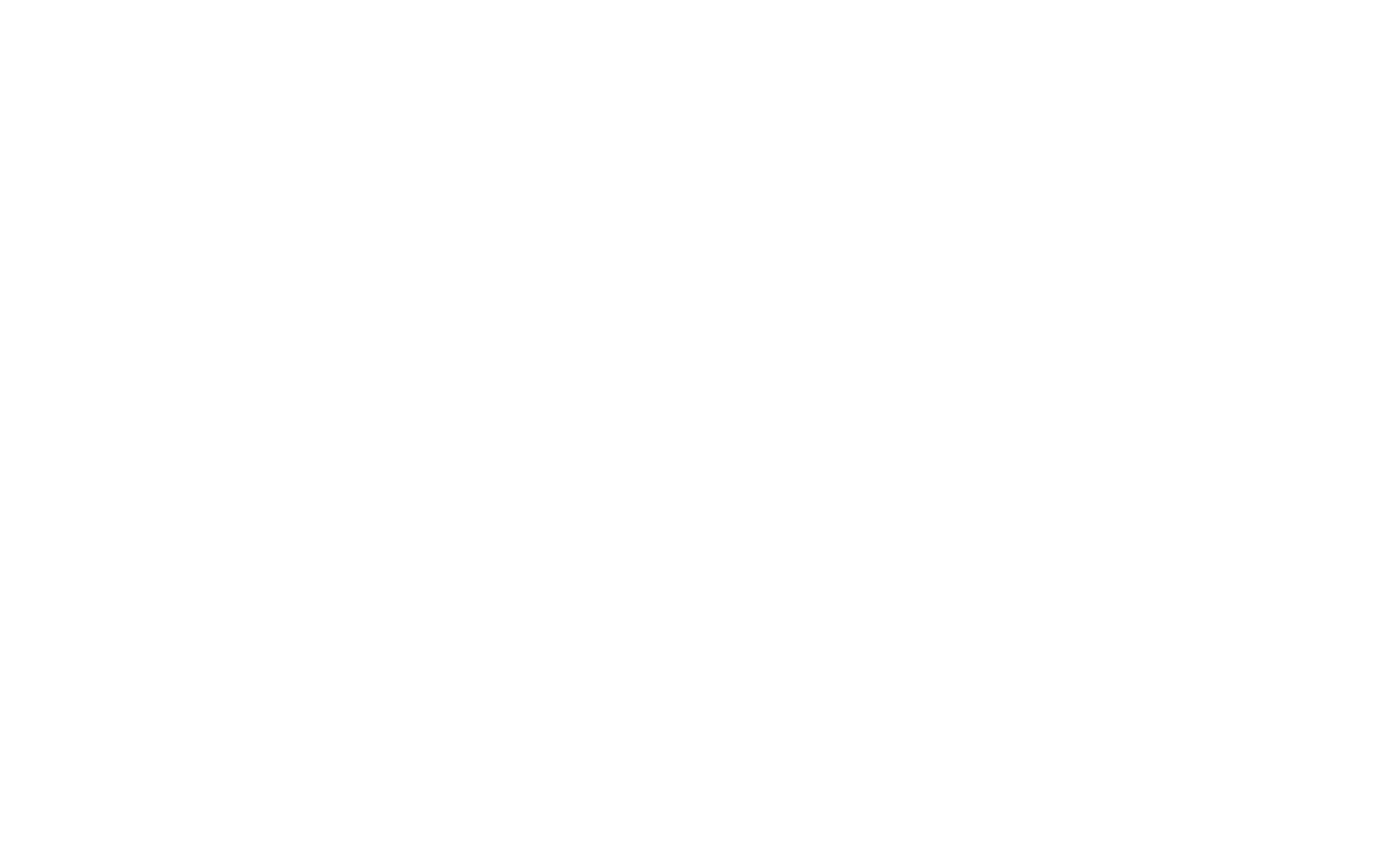

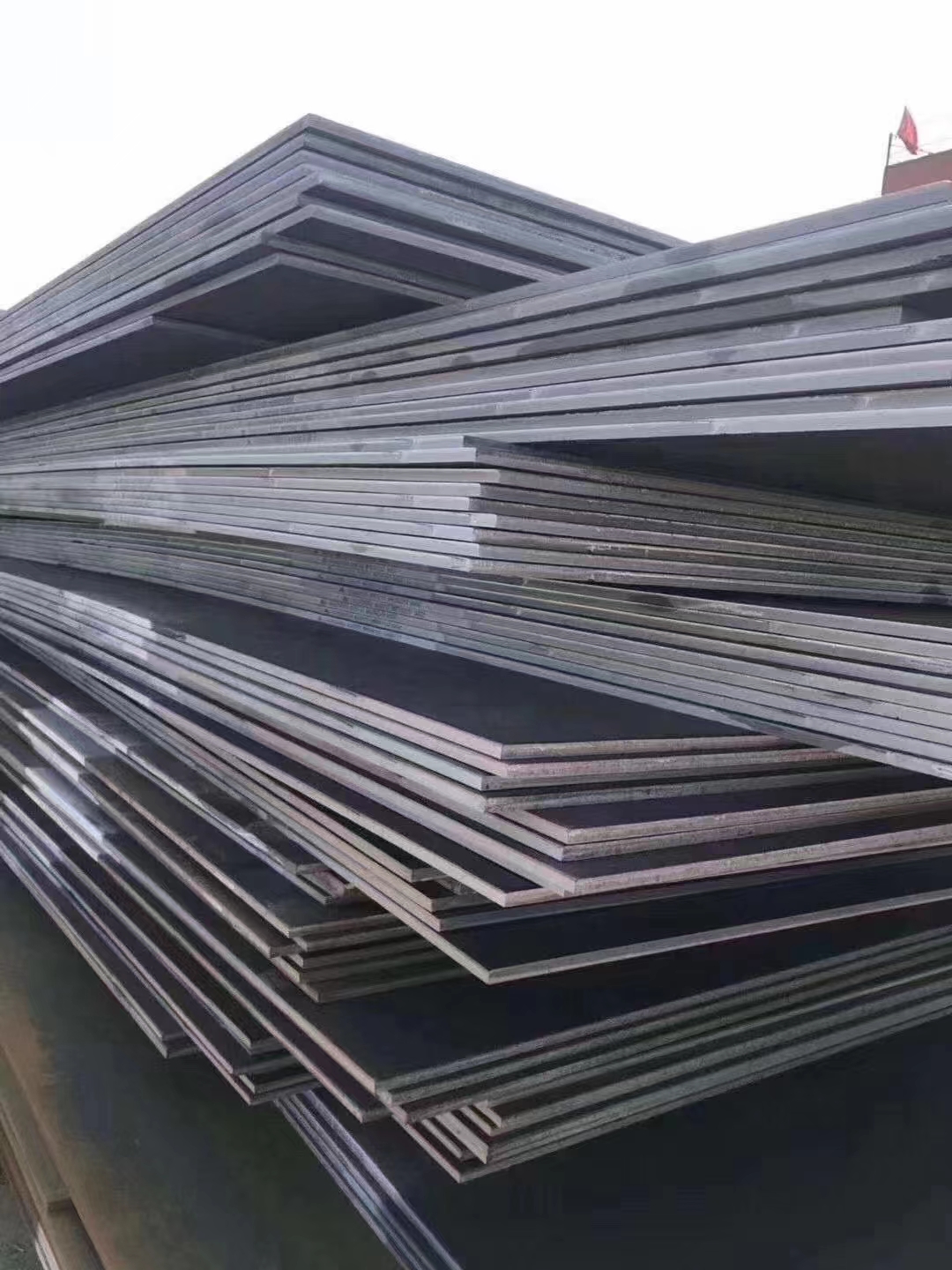

En 10219 square And Rectangular Hollow Section is made up of strong carbon steel, corrosion resistant, and ductile. The pipes can come in different types, shapes, and dimensions. The material is made up of carbon, silicon, manganese, phosphorus, sulfur, and niobium in the content. The EN 10219 Pipe Standard mandates the pipe wall thicknesses to range from 1.8mm to 14.27mm. The minimum yield strength of the pipes is 345MPa and the minimum tensile strength is 510MPa. The material could be welded without the risk of welding crack or localized corrosion risk at the welded points. The applications include oil and gas, petroleum, petrochemical, and in power plant applications. EN 10219-1 steel pipe specified for Cold formed welded structural hollow sections of non-alloy and fine grain steels.

EN 10219-1 Steel Pipe Chemical Analysis

Steel grade | Type of de-oxidation a | % by mass, maximum | ||||||

Steel name | Steel number | C | C | Si | Mn | P | S | Nb |

S235JRH | 1.0039 | FF | 0,17 | — | 1,40 | 0,040 | 0,040 | 0.009 |

S275J0H | 1.0149 | FF | 0,20 | — | 1,50 | 0,035 | 0,035 | 0,009 |

S275J2H | 1.0138 | FF | 0,20 | — | 1,50 | 0,030 | 0,030 | — |

S355J0H | 1.0547 | FF | 0,22 | 0,55 | 1,60 | 0,035 | 0,035 | 0,009 |

S355J2H | 1.0576 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

S355K2H | 1.0512 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| a. The deoxidation method is designated as follows:FF: Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al or 0,015 % soluble Al).b. The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document. | ||||||||

The tolerances on dimensions are established in accordance with EN 10219-1 steel pipe

| Characteristics | Tolerances | ||||

| Outside dimensions of side | (H,B100mm) | 1% with a min of 0.5mm | |||

| H : Longest side B : Shortest side | (100mmH,B200mm) | 0.8% | |||

| (200mmH,B) | 0.6% | ||||

| Wall thickness(T) | (T5mm) | 10% | |||

| (5mmT) | 0.50mm | ||||

| Concavity / Convexity | MAX 0.8% with a min of 0.5mm | ||||

| Squareness of sides | 901 | ||||

| External corner radius | (T6mm) | 1.6TR2.4T | |||

| (6mmT10mm) | 2.0TR3.0T | ||||

| (10mmT) | 2.4TR3.6T | ||||

| Twist | 2mm + 0.5mm/m in length | ||||

| Straightness | 0.15% in total length | ||||

| Mass | 6% in individual lengths | ||||

| Length | Approximate | 0, +50mm | |||

| Exact | L6,000mm | 0, +5mm | |||

| 6,000mmL10,000mm | 0, +15mm | ||||

| 10,000mmL | 0, +5mm+1mm/m | ||||

| NOTE 1)The outside dimensions are measured across the flats at positions at least 50mm from the end of the HSS. | |||||

| Steel Grade | Steel No. | Chemical Composition Limits (%) | |||||

| C Max. | Si Max. | Mn Max. | P Max. | S Max. | N Max. | ||

| S235JRH | 1.0039 | 0.17 | – | 1.40 | 0.040 | 0.040 | 0.009 |

| S275J0H | 1.0149 | 0.20 | – | 1.50 | 0.035 | 0.035 | 0.009 |

| S275J2H | 1.0138 | 0.20 | – | 1.50 | 0.030 | 0.030 | – |

| S355J0H | 1.0547 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | – |

| S355K2H | 1.0512 | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | – |

EN 10219-1 Steel Pipe Mechanical Properties

| Steel Grade | Steel No. | Mechanical Properties | Impact Energy (KV J) | ||||

| Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) | Test Temperature At a Test Temperature of ℃ | ||||

| -20 | 0 | 20 | |||||

| S235JRH | 1.0039 | 235 | 360-510 | 26 | – | – | 27 |

| S275J0H | 1.0149 | 275 | 410-560 | 23 | – | 27 | – |

| S275J2H | 1.0138 | 275 | 410-560 | 23 | 27 | – | – |

| S355J0H | 1.0547 | 355 | 510-680 | 22 | – | 27 | – |

| S355J2H | 1.0576 | 355 | 510-680 | 22 | 27 | – | – |

| S355K2H | 1.0512 | 355 | 510-680 | 22 | 40 | – | – |

Size Chart of EN 10219-1 Steel Pipe

| Size (mm) | Wall thickness (mm) | ||||||||||||||||||||

| Square | Rectangular | 1.6 | 2 | 2.3 | 2.5 | 3 | 3.2 | 4 | 4.5 | 5 | 6 | 6.3 | 8 | 9 | 10 | 12 | 12.5 | 16 | 19 | 20 | 22 |

| 60×30 | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| 50×50 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| 60×40 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 70×40 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 60×60 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| 75×45 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| 75×50 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 100×40 | √ | √ | √ | √ | √ | √ | |||||||||||||||

| 75×75 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||

| 100×50 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| 80×80 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| 125×40 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 125×50 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 90×90 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| 100×100 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 125×75 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||

| 150×50 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 150×75 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| 150×80 | √ | √ | √ | √ | √ | √ | |||||||||||||||

| 120×120 | √ | √ | √ | √ | √ | √ | |||||||||||||||

| 125×125 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||

| 150×100 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||

| 150×150 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||

| 175×125 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 200×100 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||

| 175×175 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| 200×150 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| 250×100 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 200×200 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| 225×175 | √ | √ | √ | ||||||||||||||||||

| 250×150 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| 300×100 | √ | √ | √ | √ | √ | √ | |||||||||||||||

| 250×200 | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| 300×150 | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| 250×250 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| 300×200 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 350×150 | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| 300×300 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||

| 350×250 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 400×200 | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| 350×350 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 400×300 | √ | √ | √ | √ | √ | ||||||||||||||||

| 400×400 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 500×300 | √ | √ | √ | √ | |||||||||||||||||

| 450×450 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 600×300 | √ | √ | √ | √ | |||||||||||||||||

| 500×500 | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||

| 550×550 | √ | √ | √ | √ | √ | √ | |||||||||||||||

Application of EN10219-1 Steel Pipe

- Bridges

- Railway Station Hall Roofs

- Airport Waiting Hall Roofs

- Trusses

- Bus Shelters

- Library Roofs

We are a professional Carbon Steel Pipe supplier. We provide Carbon Steel Pipe of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:admin@cnsteelpiping.com